To understand LEADS, first we need to understand LEAN. Lean is actually to help an organization improve for the future need, as it faces new competition and changing technological conditions. Lean, done right, makes an organization more profitable and adaptable to change as it occurs. Lean gives an organization the continuing opportunity to fulfill requirements of its customers over time. Good performance is relative. Many organizations lack communication internally, this lacking leads to a very poor work culture. If that’s all you compete against, then performance is really needed to be taken seriously. Customers expect great, not good, performance. If we are truly customer focused, then the reason we do Lean is to better satisfy customers.

Lean management is a better way to increase economic growth, which organization may face time to come. Continual improvement pays for things that an organization needs or what it must do for its interested parties. The payoff will be low and slow if leaders fail to recognize Lean as a solution to information flow problems, and which also has the knock-on effect of improving human health in organizations.

Learn-Engage-Adopt-Demonstrate-Sustain (LEADS)

LEADS is an innovative and engaging program under PMG Consultants, this program is derived after lots of enriched experience. In the last few years ILO (International Labour Organization) has initiated a SCORE program to improve the productivity of MSME across the world. PMG Consultant is lucky to be a part of the SCORE program and has helped many small and medium enterprise to grow by improving productivity.

Based on the experience of mechanical engineer and industrial engineers, the program is more refined by PMG consultants and developed in the form of Learn-Engage-Adapt-Demonstrate-Sustain, LEADS. PMG being a lean consultant or more specifically productivity consultant aims at improving organization by using various industrial tools.

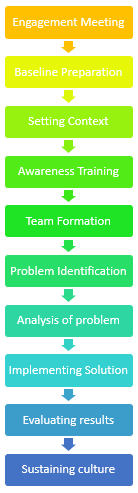

PMG’s Approach for LEADS

Tools Used

During the implementation of LEADS for continual improvement, we use various industrial tool for statistical approach during the entire phase of the program. Some of the used tools are:

Time & Motion Study: Method for identifying and recognizing employee productivity standards in which (a) a integrated task is broken into small and simple steps, (b) the sequence of motions performed by the employee in completing those tasks is carefully observed to detect and eliminate redundant or wasteful motion, and (c) precise time taken for each correct movement is measured.

5S: 5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury.

Kaizen: Kaizen is a Japanese(Nihongo) word depicting “change for the better” or “continuous improvement.” It is a Japanese business philosophy regarding the processes that continuously improve operations and involve all employees. Kaizen aims improvement in productivity gradually and methodically. The philosophy of kaizen includes a wide range of ideas. It involves making the work environment more efficient and effective by creating a team atmosphere, improving everyday procedures, ensuring employee satisfaction, and making a job more fulfilling, less tiring, and safer.

Kanban: Kanban is a visual system for managing work as it moves through a process. Kanban visualizes both the process (the workflow) and the actual work passing through that process. The goal of Kanban is to identify potential bottlenecks in your process and fix them so work can flow through it cost-effectively at an optimal speed or throughput.

Control chart: The control chart is a graph used to study how a process changes over time. Data are plotted in time order. A control chart always has a central line for the average, an upper line for the upper control limit and a lower line for the lower control limit. These lines are determined from historical data. By comparing current data to these lines, you can draw conclusions about whether the process variation is consistent (in control) or is unpredictable (out of control, affected by special causes of variation). This versatile data collection and analysis tool can be used by a variety of industries and is considered one of the seven basic quality tools.

Leadership

Leader of the Organization opting for LEADS shall assume responsibility for making the team ONE and strategically blend the continual improvement program, as the ultimate aim of any management system is to improve the performance of the organization, both in terms of business and strategy. While building LEADS base a good leader shall demonstrate a high level of understanding of the issues and build management system in the strategic interest of the organization.

PMG’s Factor

PMG consultants can be named as Lean consultant or ISO consultants which aims at developing the competence in the organization by making the employees do the work under the continuous guidance and gainful knowledge experience.